By María José Gamba

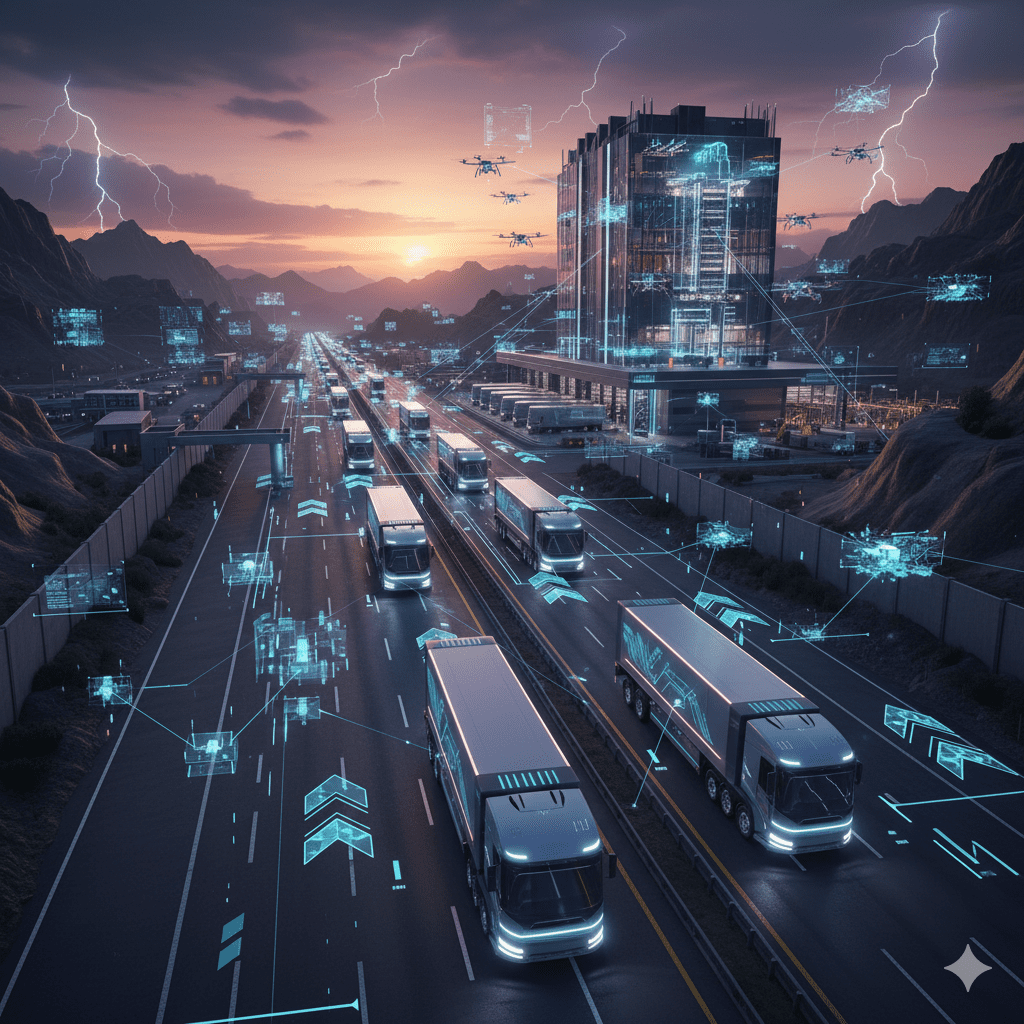

Global logistics faces a paradox of complexity: while the customer demands faster, cheaper deliveries, supply chains become longer, more vulnerable, and unpredictable. This pressure has turned efficiency from an advantage into a survival necessity. In this landscape, Generative Artificial Intelligence (GAI)—the same technology that creates text and images—is emerging as the most powerful tool to transform operational planning. GAI allows transportation and logistics companies to not only react to historical data but to generate predictive solutions that address risk scenarios before they materialize, a crucial factor in the dynamic North American trade corridor.

Moving Beyond Static Optimization with Large Language Models (LLMs)

Traditionally, logistics optimization (both route planning and warehouse space) has relied on linear programming algorithms or management systems operating with fixed rules and historical data. These methods are fast but fragile in the face of real-world unpredictability, such as an unexpected protest on I-35 leading to the border, or an unpredicted peak in demand.

GAI, on the other hand, uses Large Language Models (LLMs) and advanced neural networks to interpret a massive data pool that includes: traffic patterns, weather reports, geopolitical news, social media, and transactional data. By processing this unstructured information, GAI can simulate thousands of scenarios and generate a “contextualized prediction,” surpassing the simple calculation of the shortest distance.

This generative capability allows the system to answer complex questions like: “Given current security conditions, the price of diesel, and the probability of a delay at the Laredo Customs Port, which route offers the lowest total cost-risk for this critical shipment?”

Impact on Cross-Border Route Planning

The application of GAI in fleet management directly impacts profitability and safety in high-volume corridors like the US-Mexico supply chain.

Dynamic Risk Analysis: Instead of assuming an average transit time, GAI evaluates the probability of incidents (theft, blockades, accidents) on each route segment. If it detects an increase in criminal activity in a specific area, it automatically generates an alternative route and a new security plan that includes certified secure stopping points (C-TPAT/FAST), notifying both the driver and the monitoring center.

Load and Unload Optimization (LTL): For Less-than-Truckload (LTL) shipments, GAI is invaluable. It can analyze hundreds of orders and generate the pickup and delivery sequence that not only minimizes mileage but also ensures that delivery time windows are met, even with slight delays. The model generates the truck loading plan, maximizing volume utilization and minimizing damage to goods.

Hours-of-Service (HOS) and Compliance Management: GAI integrates the Hours of Service regulations on both sides of the border (US and Mexico). The system accurately predicts when a driver will need to stop and generates the closest and safest rest area, ensuring legal compliance and operator well-being.

Transforming Smart Distribution Centers (Generative WMS)

Within warehouses and distribution centers, GAI is taking the Warehouse Management System (WMS) to a higher level, turning it into a Generative WMS that self-optimizes.

Layout Design by Demand: Instead of relying on a fixed layout, AI can analyze the volatility of nearshoring and e-commerce peaks. If it detects that the demand for an automotive product from a new plant will skyrocket in the next quarter, it virtually generates a new layout, relocating the SKU to the most efficient picking zones to reduce operator travel times.

Intelligent Resource Allocation: GAI analyzes the productivity of operators, congestion in packing zones, and the flow of forklifts in real-time. Based on this information, it generates and assigns tasks to each person and robot, ensuring there are no bottlenecks and that the error rate remains minimal.

Predictive Inventory Simulation: A generative model not only tells you how much inventory you have, but it simulates how changes in the economy (a new tariff, a port strike) will affect availability over the next 12 weeks, proactively generating recommendations to stock up or accelerate orders.

Key Challenges for Logistics Adoption

The implementation of GAI requires a solid data foundation. The main hurdle for companies in the region is data fragmentation. For a generative model to work, it needs seamless access to data from TMS, WMS, telematics systems, and security reports. Initial investment must focus on the standardization and centralization of these datasets.

Furthermore, the technology must be viewed as a strategic assistant for human talent, not as a replacement. Training in prompt engineering and data analysis becomes essential so that logistics managers can ask the right questions to the model and make decisions based on the generated intelligence.

Self-Generated Efficiency as a Growth Strategy

Generative Artificial Intelligence represents a paradigm shift: efficiency is no longer sought in a report but is autonomously generated by the systems. For transportation companies operating with thin margins and facing high operational volatility across the continent, this technology is the key to risk mitigation and competitive differentiation. Adopting GAI means moving beyond reaction and entering the era of proactive, predictive logistics. In the current complex ecosystem, its ability to optimize every movement and every square foot is what will separate the leaders from the laggards.

At America’s Freight Forwarding, we are integrating predictive AI solutions to offer our clients a supply chain that is not only secure and reliable but also inherently intelligent. If you wish to learn how this technology can redefine the profitability of your cross-border operation, contact us for an asset optimization consultation.