By María José Gamba

By: Americas Forwarding Editorial Team January 19, 2026

For decades, the trucking and freight industry was built on a linear logic: pick up at Point A, deliver at Point B. Success was measured solely by outbound speed. However, as we kick off 2026, the rules of the game have shifted 180 degrees. Today, the real logistical battlefield isn’t just how goods reach the customer, but how efficiently they flow back when the “boomerang” hits.

Reverse logistics has evolved from a “back-office headache” into a multi-billion dollar drain on margins for North American companies. With the explosion of cross-border e-commerce and high-tech manufacturing between the U.S. and Mexico, freight forwarders can no longer treat returns as an operational afterthought. At Americas Forwarding, we see it as a mandatory competitive edge.

1. The Hidden Cost of Cross-Border Returns

In 2025, industrial and premium retail returns in the U.S. reached record highs. By this first quarter of 2026, estimates suggest that 1 in 4 products moved via long-haul trucking across the US-MX border will require some form of return management.

The challenge lies in the complexity of international borders. Moving freight backward through customs is up to 40% more expensive than the initial delivery if not planned strategically. At Americas Forwarding, we’ve observed that failing to address “Empty Miles” is what sinks profitability. It’s not just about bringing a pallet back; it’s about “Continuous Moves”—integrating that return into an existing lane so the truck never runs empty.

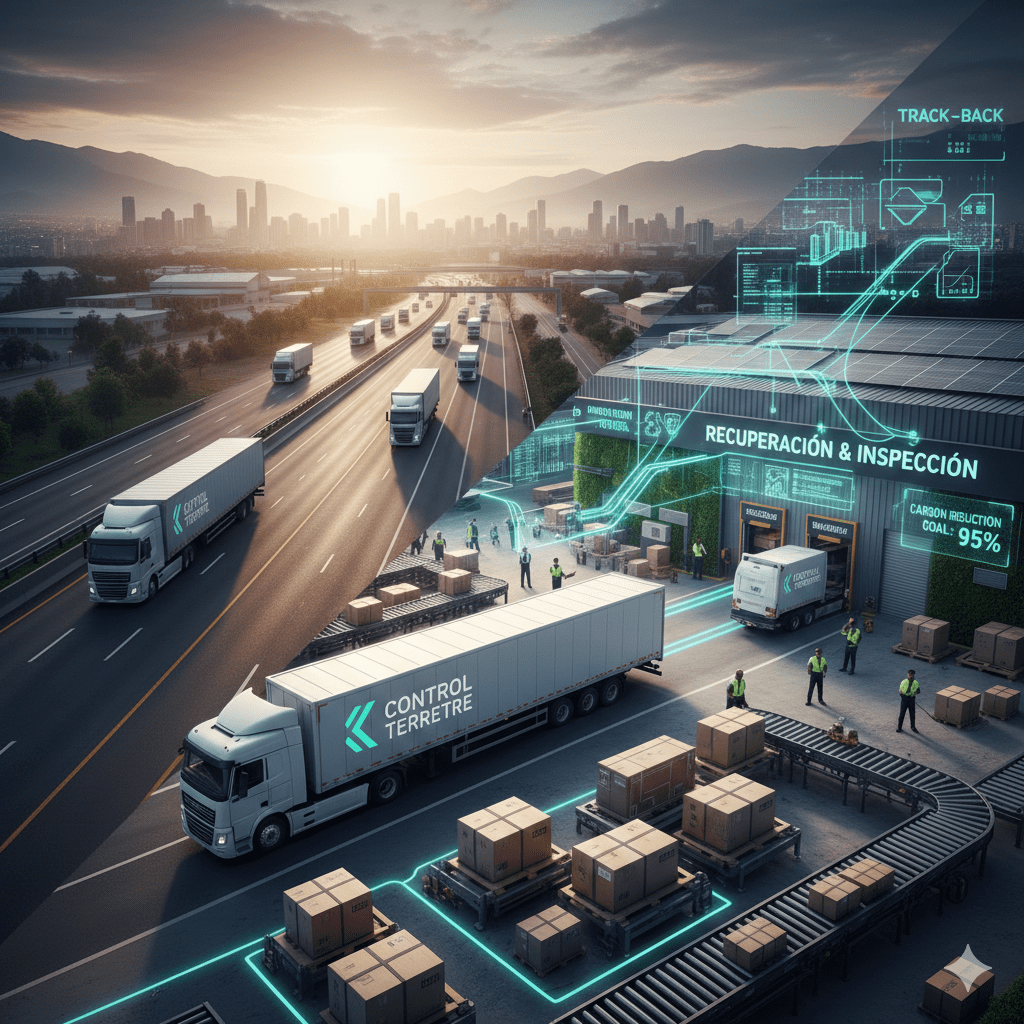

2. “Track-Back” Technology: Two-Way Visibility

A major pain point in the U.S. market is the difficulty of tracking a return with the same precision as an outbound shipment. While the original delivery has barcodes, security seals, and guaranteed ETAs, the return is often chaotic and opaque.

In 2026, the implementation of Dual-Way IoT sensors is allowing our dispatchers to know exactly what freight is returning, its condition, and whether it can be redirected to a new customer without returning to the main distribution center. This technique, known as Reverse Cross-Docking, is the trend separating logistical leaders from the rest of the pack in the US-MX corridor.

3. Sustainability: Returns Don’t Have to be “Dirty”

With the new EPA (Environmental Protection Agency) and international carbon mandates taking full effect this January, American companies are under intense scrutiny. Reverse logistics, by nature, can double the carbon footprint of a single sold item.

To counter this, Americas Forwarding is spearheading the use of Consolidation Return Hubs. Instead of dispatching a heavy-duty unit for a single return, we use strategically located intermediate centers in border cities like Laredo and El Paso to consolidate return freight. In 2026, sustainability isn’t just a “green logo” on a box; it’s an optimized cost structure that eliminates redundant trips.

4. Nearshoring and Technical Warranty Logistics

As the “Nearshoring” boom matures in 2026, Mexico isn’t just exporting finished goods; it’s exporting complex machinery. This has created a surge in Technical Reverse Logistics: the movement of high-value components or machinery that requires specialized repair under warranty.

Cross-border freight must be prepared to handle much stricter security and insurance protocols for returns. A damaged machine returning to a factory in Querétaro or Monterrey is often more fragile and costly to move than a new one. Specializing in these “Critical Return Loads” is where Americas Forwarding provides the most value to our industrial clients.

The Future: From Distribution Centers to Recovery Centers

Looking ahead through 2026, North American warehouse infrastructure is transforming. Facilities are no longer just for storage; they are dedicating up to 30% of their floor space to Immediate Inspection and Refurbishment.

Trucking is the connective tissue of this new circular system. Those who master moving freight in both directions with equal precision will win customer loyalty and maintain financial health.

Conclusion

Reverse logistics is no longer the “ugly duckling” of the supply chain. It is a golden opportunity to prove efficiency, environmental responsibility, and technological prowess. In this new year, the message for Logistics Directors is clear: If you want to move forward, make sure you know how to handle the way back.

Is your 2026 freight strategy ready for the true cost of returns? At Americas Forwarding, we optimize your lanes so every mile—outbound or inbound—delivers value. Contact us today for a 2026 cross-border efficiency audit.